Design and Prototyping Services

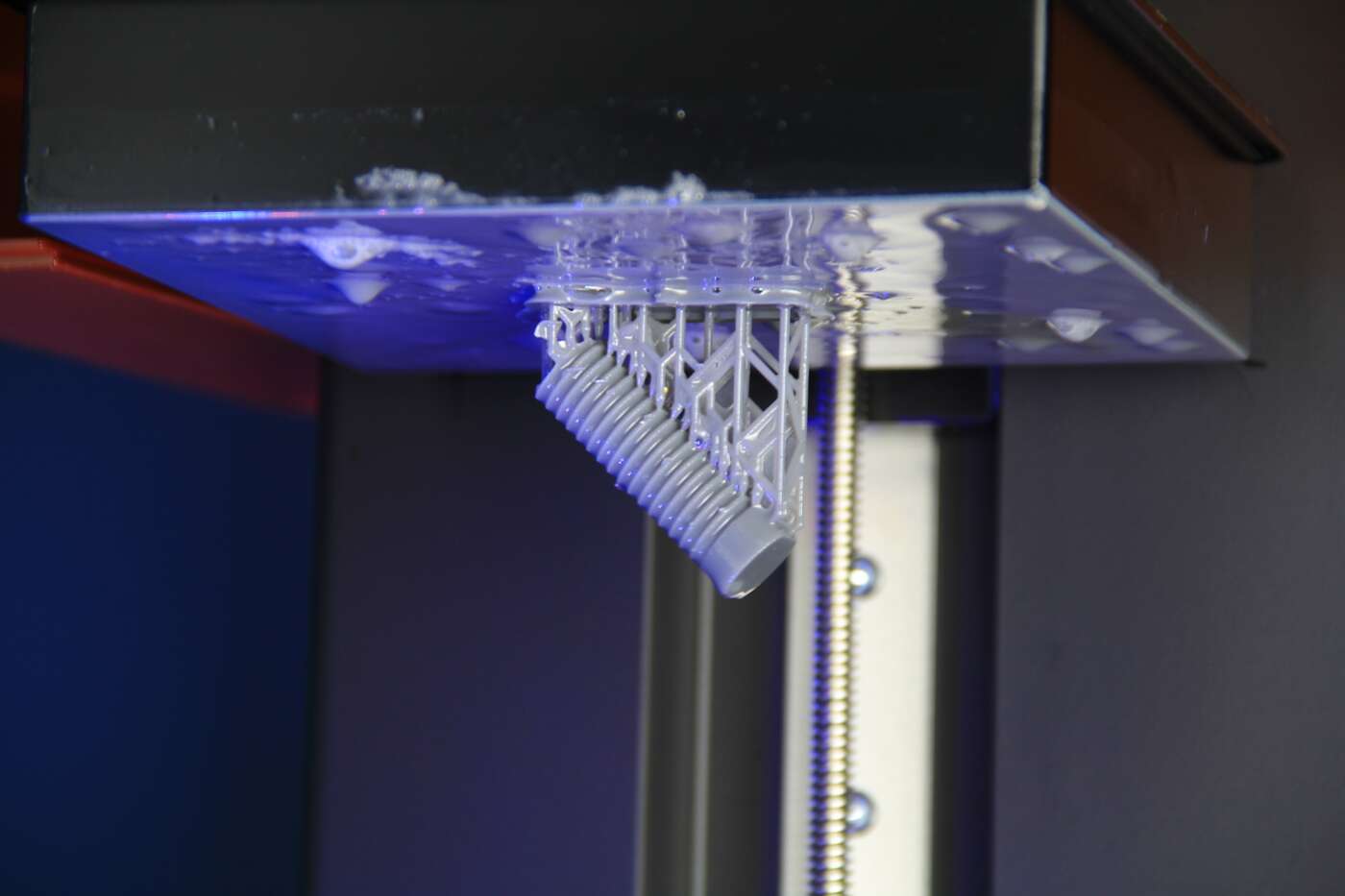

Once our team and client have agreed on a design, we move onto product prototyping. Panova’s custom prototyping services include 3D-printed samples in a variety of materials and durometers, functional mock-ups from a combination of different manufacturing processes, and samples from prototype tooling using the proposed production manufacturing process.

Detailed Project Specification Development and Reverse Engineering

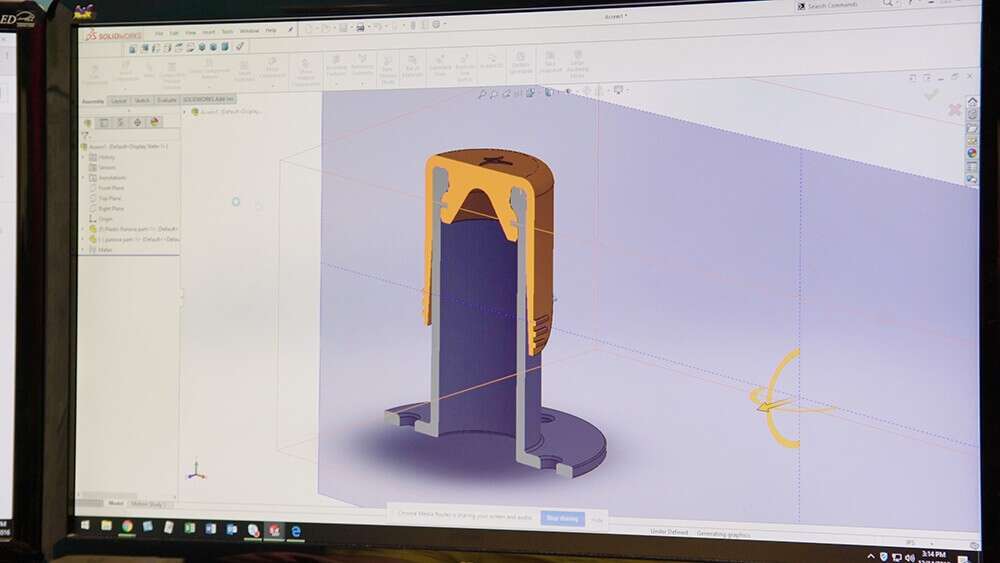

It is not uncommon that our clients approach Panova with a product or component that had been manufactured years ago, and have nothing other than a sample and a hand drawing or schematic, and are in the need for new tooling or production in a new material. In such instances, our team can reverse engineer the product through 3D computer modeling using SolidWorks and look for ways to improve the product design.

Prototype 3D Modeling and Design for Manufacturability (DFM)

Once 3D models of your product or components are available, we analyze structural integrity, manufacturability and material flow. Once our team and client have come to a design they each feel good about, we move into product prototyping:

- 3D-printed samples in a variety of materials and durometers.

- Functional mock-ups from a combination of different manufacturing processes.

- Samples from prototype tooling using the proposed production manufacturing process.

These form, fit, and function samples give the entire team an “up-close” feel for the proposed design before committing to the final design and production tooling. These samples often help alleviate potential concerns and allow the client to see design details they may have originally missed when looking at the drawing or rendering.

Custom Prototype Manufacturing Services and Supply Chain Optimization

Our team makes a concerted effort to design products that streamline the total manufacturing process and eliminate “in the field” issues as early as possible, while still adhering to all required design parameters. Using SolidWorks, our engineering team provides 3D models and 2D engineering drawings that can be generated from scratch or as the result of a reworked original model provided by the client.

A Single-Source Engineering, Prototyping, and Manufacturing Provider

Panova works as your single source to bring a component or complete product from conception to production. With an intelligent, experience-based design approach, we assist our clients with technical brainstorming, reverse engineering, material selection, manufacturing process analysis, prototyping, tooling, and production validation.